- High Performance

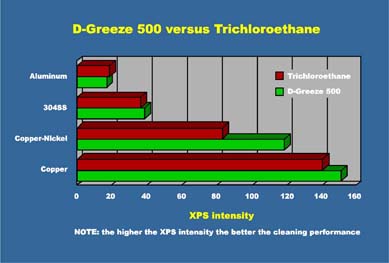

- Outperforms Trichloroethane

- Top 10 Environmental Product

- Minimizes Health and Safety Hazards

D-Greeze™ 500-LO Degreaser/Cleaner

D-Greeze 500-LO is a breed of non-hazardous cleaner that cleans quickly at room temperature. It is the first safe degreaser/cleaner to outperform trichloroethane (based on independent testing at a major U.S. university).

Unlike aqueous and many other non-hazardous cleaners, D-Greeze 500-LO does not force you to compromise performance for safety. It can be used in most existing equipment including immersion tanks, ultrasonic systems, and parts washers with little or no modification.

Suitable for use with all ferrous as well as non-ferrous metals including sensitive metals such as aluminum, titanium, brass, and magnesium, D-Greeze 500-LO enables you to meet today's more stringent workplace requirements.

For waste reduction and economy, D-Greeze 500-LO lasts 2½ times longer than a chlorinated solvent.

Cleaning with D-Greeze™ 500-LO

D-Greeze 500-LO's aggressive cleaning action penetrates, dissolves, and removes lubricating oils, grease, cosmolin, adhesive deposits, and other contaminants. With its low surface tension, low viscosity and superior cleaning properties, D-Greeze 500-LO quickly penetrates and cleans even very small orifice openings, blind holes and other difficult to clean surfaces.

Because D-Greeze 500-LO is designed to dissolve, emulsify and remove oils and greases without allowing the oils to surface, when parts are removed from a tank, they are not recontaminated.

Best degreasing cleaning results are achieved by total immersion and agitation. Since D-Greeze 500-LO cavitates very well, it is suitable for use in ultrasonic equipment without the use of heat.

Quick Drying Options

As a non-hazardous and non-polluting degreaser/cleaner, D-Greeze 500-LO is slow to evaporate. To meet fast production rates, drying needs to be induced.

For quick drying requirements D-Greeze can be mechanically dried in seconds by air blow off, leaving parts dry, spotlessly clean and residue free. The drying should take place in an enclosed ventilated chamber and the stripped-off liquid collected for reuse.

Blow-off drying can be accomplished by using a simple hand-held mini air knife or an automated, in-line high penetration air knife drying system. The low pressure, high velocity air, is blower supplied.

Using D-Greeze™ with Existing Equipment

D-Greeze 500-LO enables you to replace hazardous conventional and chlorinated solvents without having to invest in new capital equipment. You can use D-Greeze with just about any type of degreasing/cleaning equipment with good local exhaust ventilation including:

- vapor degreaser's tank (add agitation, disconnect heating)

- immersion

- soak and agitate

- spray (low pressure, no atomization)

- ultrasonic systems (no heating)

- parts washers

- rag wipe

D-Greeze· 500-LO eliminates problems associated with water-based cleaners including: low performance, expensive deionized water rinsing, the high cost of new equipment, expensive waste water treatment, corrosion potential, high water consumption with rising sewer fees, and ground water pollution potential, as well as the water heating cost.

Minimizes Health and Safety Hazards

D-Greeze 500-LO is a non-hazardous degreaser which contains no halogens, CFCs, or SARA-listed chemicals.

It is non-carcinogenic, non-flammable, non-reactive, and non- corrosive. Additionally, air pollution potential is minimal. Unlike conventional solvents, D-Greeze 500-LO has a very low degree of acute oral and inhalation toxicity and is free of aromatic or chlorinated components.

Meets Federal and State Regulations

Section 313 of the Superfund Amendment and Reorganization Act (SARA) mandates that a facility must report to the EPA the use and release of specific toxic chemicals. D-Greeze 500 does not contain any of the components listed in Section 313 toxic chemical list. And, as defined in the Clean Air Act Amendment of 1990, D-Greeze 500 is not a hazardous air pollutant.

D-Greeze 500-LO contains no aromatics and is non-photochemically reactive which makes it compatible with air quality requirements. With 0.7 vapor pressure at 68°F, it is below the specified limit and meets regulatory exempt status in many states. By comparison, the vapor pressure at 68°F (20°C) of 1,1,1 Trichloroethane is 100 MM Hg.